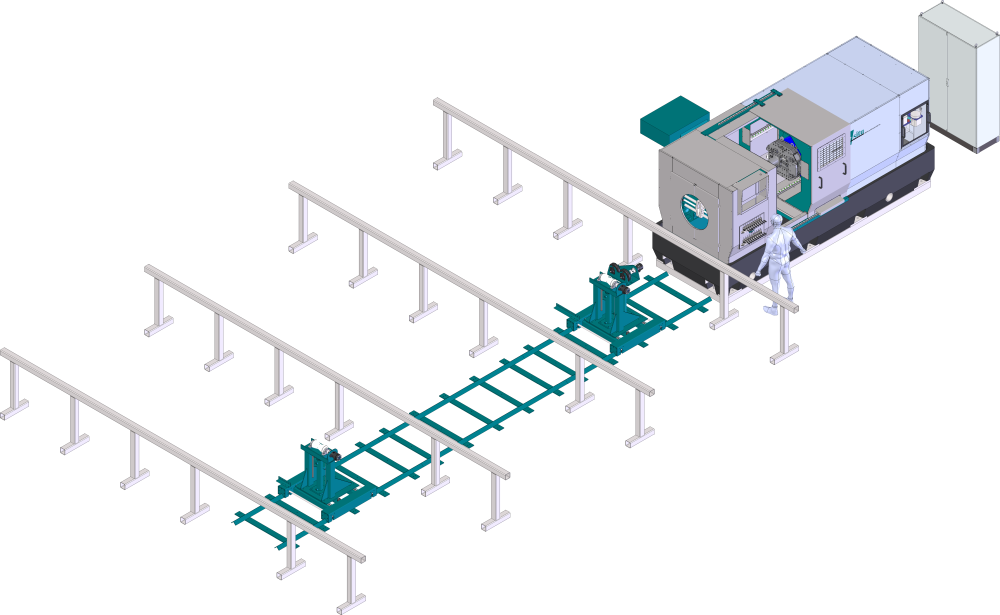

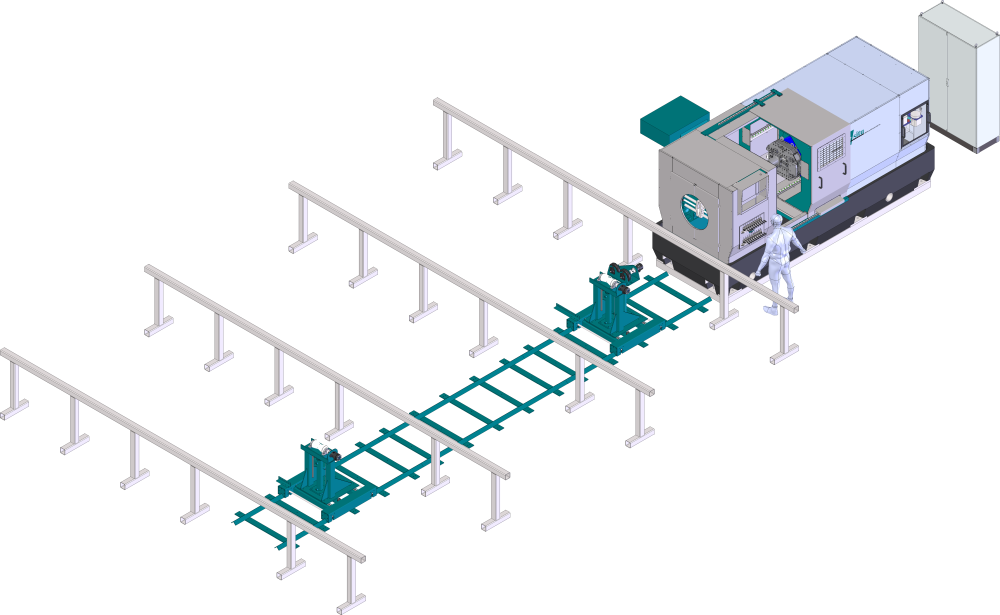

DD Machine

Standard Ø20” Series 2000 DD machine

Fanuc 32i-B Series control mounted in a custom pendant

Fanuc Screen display function with remote access

CE marked Rittal enclosure housing all control gear and associated equipment

Harsh environment Type 4 Air conditioner for Rittal enclosure

In-Situ Rotating head with CNC controlled X Axis movement to allow turning operations on stationary pipe

37kW S1 Rating Fanuc AC Spindle motor

Z Axis linear movement by three precision preloaded linear bearings

Dual preloaded precision ballscrews on Z Axis

X axis Pulse Coder feedback

Z axis Pulse Coder feedback

In-Situ 4 Jaw Chuck Ø21” through bore

In-Situ 3 Jaw Chuck with Ø12” through bore

Vee type adjustable rear pipe steady which provides for repeatable alignment of pipe during batch runs

Pipe handling system to feed Ø2 3/8” - Ø20” pipe

Hydraulic power pack to suit

Fully integrated coolant system

Through spindle coolant

Swarf conveyor

Completely enclosed machine guarding, operator sliding access door with safety interlock system