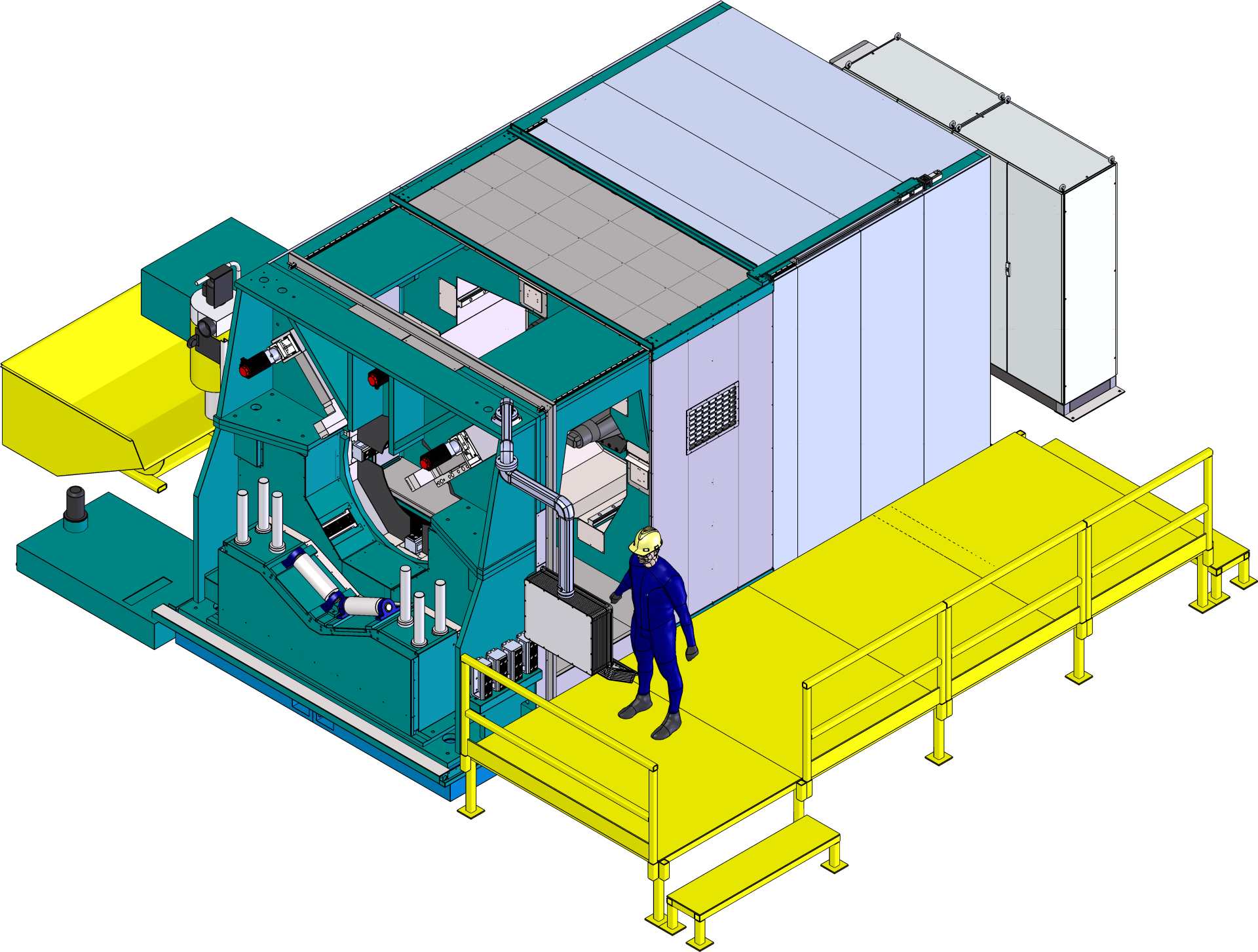

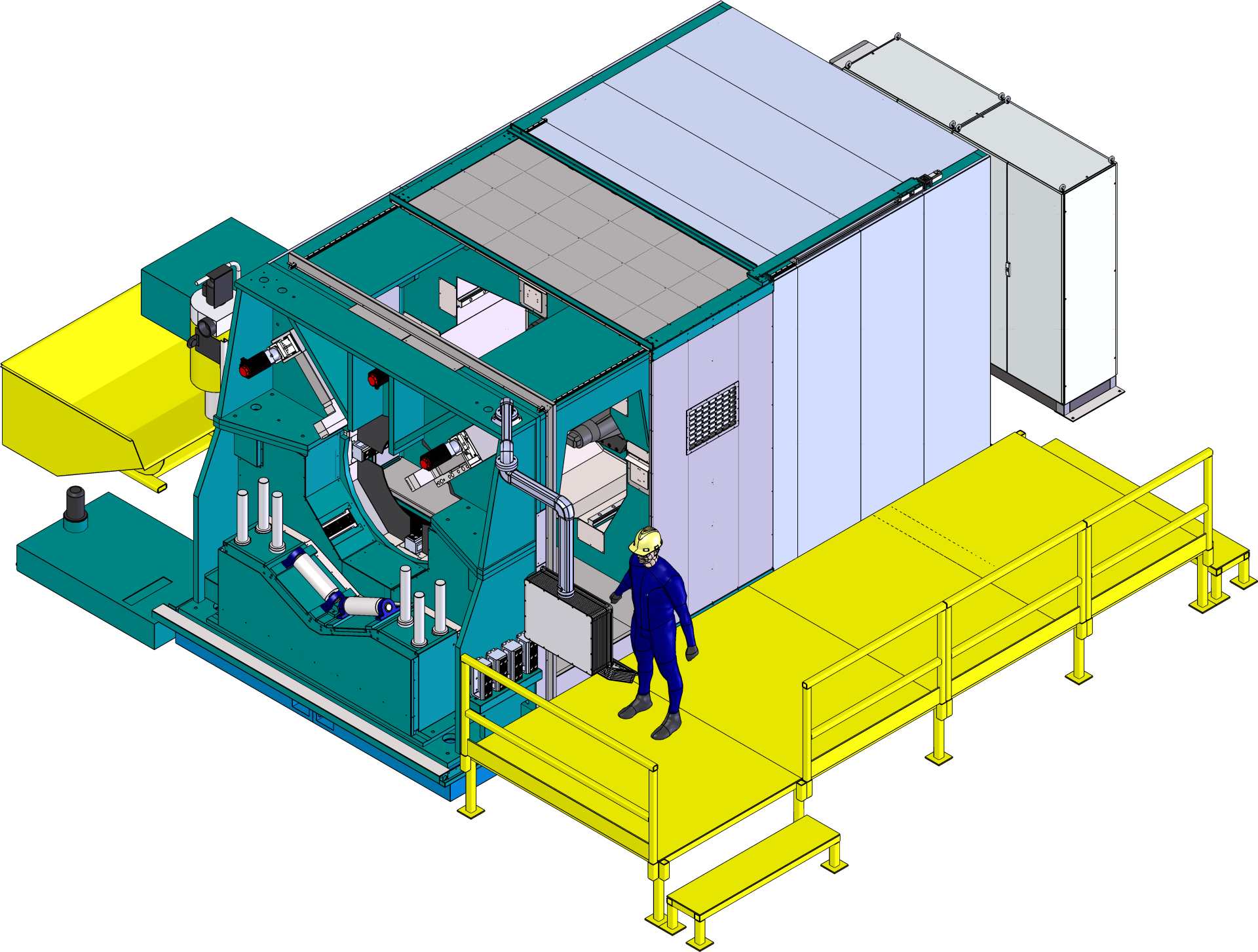

XL Machine

Based on our Standard Ø48” Series machine (machining capacity Ø20” - Ø48”)

Fanuc 30i-B Series control mounted in a custom pendant

Fanuc Handy Operators panel (HMOP)

Rotating head with CNC controlled X Axis movement to allow turning operations on stationary pipe.

In-Situ CNC Controlled “V” type roller mechanism, utilising our Patented “Pendleslide” technology for pipe alignment

In-Situ standard 8 Jaw chucking system with Servo controlled Front 4 Jaw chucking system with special high axial contact jaws and hydraulic activated rear Jaws

CNC control Auto-Alignment and clamping via Custom Fanuc Picture screen

60kw Fanuc AC Spindle motor

2 Stage(Coolant and Air) rotary union combined electrical slip ring for X Axis feedback device

4 off High precision laser devices for Non-Contact measurement of pipe diameter during alignment process

4 off Servo Controlled linear slide mechanisms to advance and retract laser devices during alignment process

Z Axis linear movement by four precision preloaded linear bearings (Increased from three)

Dual preloaded precision ballscrews on Z Axis

Heidenhain® Scale feedback on Z Axis (Fully closed Loop) with Dual position Feedback

X Axis (Fully closed loop)

Renishaw RMP60 probe with radio receiver fully interfaced with the 30i-B control and subsequent remote PC

Electro/mechanical brake for C axis clamping use during probing cycles

Rittal enclosure housing all control gear and associated equipment

Hydraulic power pack to suit

Fully integrated coolant system with paper band filter system

Through spindle coolant

Swarf conveyor

Completely enclosed machine guarding, powered operator sliding access door with safety interlock system.

Fanuc Screen display function with remote access